Silicone rubber strip is a highly versatile product that offers exceptional sealing capabilities, insulation properties, and ease of assembly. Crafted from top-quality silicone rubber and infused with high-efficiency flame retardant, this product is designed to meet the demanding requirements of various industries, including semiconductor equipment and electronic appliances.

The primary purpose of the silicone rubber strip is to provide a reliable and efficient sealing solution. Its high-performance silicone rubber composition ensures a tight and secure seal, effectively preventing the leakage of fluids, gases, or other substances. This sealing capability is crucial in applications where maintaining a controlled environment is essential, such as in semiconductor equipment.

| Availability: | |

|---|---|

| Quantity: | |

GC-JS50

Gold-cool

ISO9001

The silicone rubber strip is a high-performance sealing solution that offers exceptional benefits across various industries. Its outstanding sealing capabilities, rebound properties, insulation, shock-proof features, and ease of assembly make it an indispensable component in the sealing and bonding of semiconductor equipment, electronic appliances, and other machinery. By providing a reliable and efficient seal, the silicone rubber strip ensures the protection, longevity, and optimal performance of equipment, ultimately contributing to the success and advancement of numerous industries.

Product Parameters

| General Product Attribute Table | |||

| Project | Unit | GC-JS50 | Testing Standard |

| Color | - | Orange | Visual |

| Hardess | Shore oo | 50±5 | ASTM D2240 |

| Density | g/cm3 | 1.2±0.2 | ASTM D792 |

| Volume resistance | Ω .cm | >1.0*1012 | ASTM D257 |

| Compressive permanent deformation rate | - | ≤10% | GB/T 7759 |

| Tensile strength | Mpa | ≥2.5 | ASTM D412 |

| Roll length | m | 100 | - |

| Temperature Range | ºC | -40~200 | - |

| Breakdown voltage | KV | ≥4 | ASTM D149 |

Case Sharing

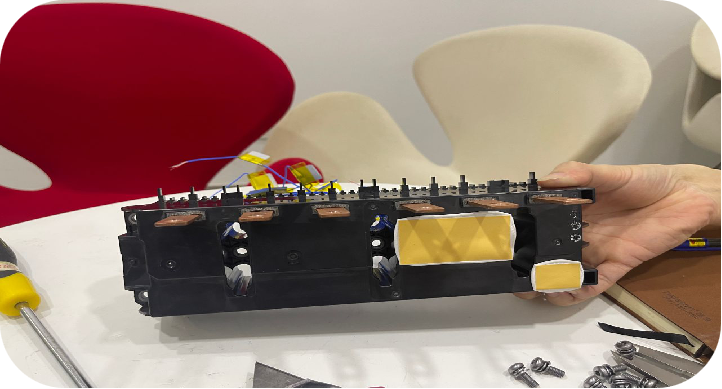

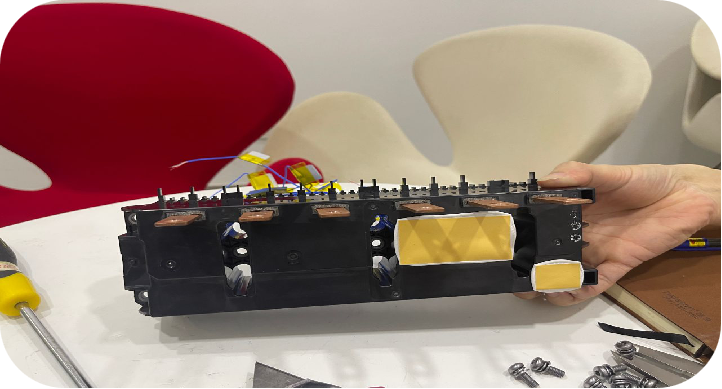

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

Features

1.Good sealing performance

2.Shockproof and high pressure resistant

3.Resilience is good

4.Acid, alkali and corrosion resistance

5.Meet ROHS

Application:

1.Lamp sealing, industrial refrigeration equipment

2.Mechanical equipment, household appliances seal

3.Telecommunications industry, automotive electronic equipment

4.Other sealing and shock-proof scenarios

FAQ

Q1:How long does it take to ship an order? How long does the shipping time take?

A1:We usually ship within 7 days after receiving the order, and the shipping time is 10-15 days.

Q2:What's your shipping way?

A2:We can provide rail transportation and sea transportation, samples can be sent by international express, the specific mode of transportation and freight need to be negotiated.

Q3:What's your payment term?

A3:Our normal payment is T/T.

Q4:Do you have after-sales service?

A4:Yes,we provide 24-hour online technical guidance, timely reply to your difficulties encountered in the process of use.

The silicone rubber strip is a high-performance sealing solution that offers exceptional benefits across various industries. Its outstanding sealing capabilities, rebound properties, insulation, shock-proof features, and ease of assembly make it an indispensable component in the sealing and bonding of semiconductor equipment, electronic appliances, and other machinery. By providing a reliable and efficient seal, the silicone rubber strip ensures the protection, longevity, and optimal performance of equipment, ultimately contributing to the success and advancement of numerous industries.

Product Parameters

| General Product Attribute Table | |||

| Project | Unit | GC-JS50 | Testing Standard |

| Color | - | Orange | Visual |

| Hardess | Shore oo | 50±5 | ASTM D2240 |

| Density | g/cm3 | 1.2±0.2 | ASTM D792 |

| Volume resistance | Ω .cm | >1.0*1012 | ASTM D257 |

| Compressive permanent deformation rate | - | ≤10% | GB/T 7759 |

| Tensile strength | Mpa | ≥2.5 | ASTM D412 |

| Roll length | m | 100 | - |

| Temperature Range | ºC | -40~200 | - |

| Breakdown voltage | KV | ≥4 | ASTM D149 |

Case Sharing

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

Features

1.Good sealing performance

2.Shockproof and high pressure resistant

3.Resilience is good

4.Acid, alkali and corrosion resistance

5.Meet ROHS

Application:

1.Lamp sealing, industrial refrigeration equipment

2.Mechanical equipment, household appliances seal

3.Telecommunications industry, automotive electronic equipment

4.Other sealing and shock-proof scenarios

FAQ

Q1:How long does it take to ship an order? How long does the shipping time take?

A1:We usually ship within 7 days after receiving the order, and the shipping time is 10-15 days.

Q2:What's your shipping way?

A2:We can provide rail transportation and sea transportation, samples can be sent by international express, the specific mode of transportation and freight need to be negotiated.

Q3:What's your payment term?

A3:Our normal payment is T/T.

Q4:Do you have after-sales service?

A4:Yes,we provide 24-hour online technical guidance, timely reply to your difficulties encountered in the process of use.