In the realm of sealing rubber strip products, continuous innovation and improvement are essential to meet the ever-evolving demands of various industries. One such advancement is the integration of conductive extrusion shielding strips, which significantly enhance the performance and functionality of waterproof sealing solutions. Through extensive testing and meticulous comparisons, it has been determined that the primary material for achieving optimal waterproof sealing is silicone, while the shielding conductive materials primarily consist of nickel carbon, silver aluminum, conductive cloth, and other similar elements.

| Availability: | |

|---|---|

| Quantity: | |

GC-SP -YB65

Gold-cool

ISO9001, ISO14001, UL, Rohs, IATF16949, Reach

The advantages of utilizing sealing silicone shielding strips, combined with the conductive extrusion shielding strips, are manifold. Firstly, the silicone material ensures exceptional water resistance, making it ideal for applications where protection against moisture is paramount. Additionally, the incorporation of conductive materials within the extrusion shielding strips guarantees effective EMI and RFI shielding, thereby preventing signal interference and maintaining the integrity of electronic systems.

Product Parameters

| Model | GC-SP -YB65 | unit | Testing Standard | |||||||||||||||||

| Sealing material | Silver coated glass | / | / | |||||||||||||||||

| color | yellowish-brown | / | / | |||||||||||||||||

| Volume resistivity | 0.01 | Ω *cm | MIL-DTL-83528E | |||||||||||||||||

| hardness | 65 | Shore A | ASTM D2240 | |||||||||||||||||

| tensile strength | ≥2.0 | MPa | ASTM D412 | |||||||||||||||||

| elongation at break | 400 | % | ASTM D412 | |||||||||||||||||

| compression set | 20 | % | ASTM D395 | |||||||||||||||||

| Resistance after aging | 0.01 | Ω *cm | ENG-WI-550RevA2 | |||||||||||||||||

| density | 1.9 | g/cm3 | ASTM D792 | |||||||||||||||||

| Shielding energy efficiency | - | dB | MIL-DTL-83528E | |||||||||||||||||

| Operating temperature | -55-160 | ℃ | / | |||||||||||||||||

| Mold proof grade | 0 | / | GB/T 2423.16-2008 | |||||||||||||||||

Case Sharing

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

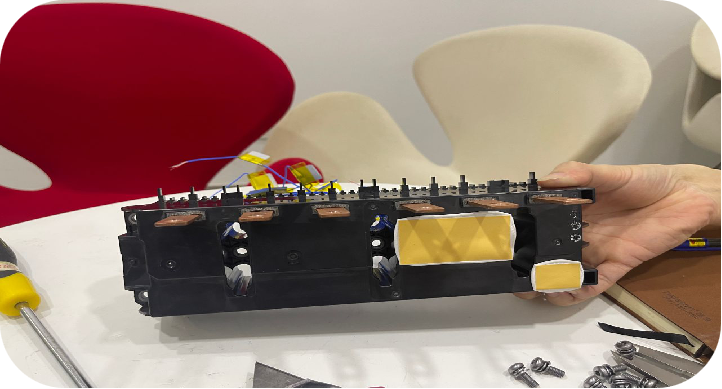

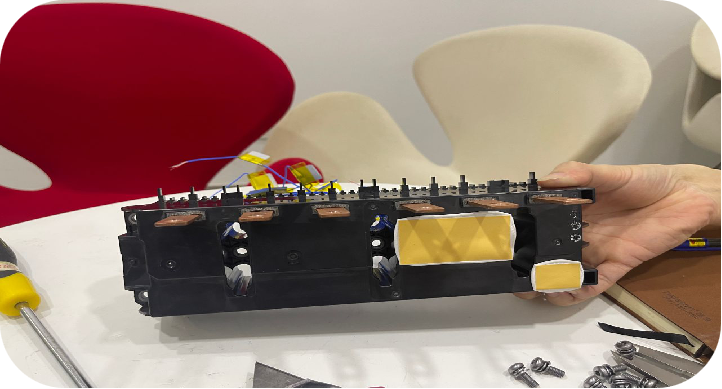

Case background 2: The customer's controller needs to be sealed with waterproof tape. It is required to reach the waterproof rating of IP67 and IP68 to ensure that the sealing is waterproof.

The use of our single-sided adhesive extrusion hollow rubber strip, through customer testing and verification, can well meet the customer's sealing and waterproof requirements.

The advantages of utilizing sealing silicone shielding strips, combined with the conductive extrusion shielding strips, are manifold. Firstly, the silicone material ensures exceptional water resistance, making it ideal for applications where protection against moisture is paramount. Additionally, the incorporation of conductive materials within the extrusion shielding strips guarantees effective EMI and RFI shielding, thereby preventing signal interference and maintaining the integrity of electronic systems.

Product Parameters

| Model | GC-SP -YB65 | unit | Testing Standard | |||||||||||||||||

| Sealing material | Silver coated glass | / | / | |||||||||||||||||

| color | yellowish-brown | / | / | |||||||||||||||||

| Volume resistivity | 0.01 | Ω *cm | MIL-DTL-83528E | |||||||||||||||||

| hardness | 65 | Shore A | ASTM D2240 | |||||||||||||||||

| tensile strength | ≥2.0 | MPa | ASTM D412 | |||||||||||||||||

| elongation at break | 400 | % | ASTM D412 | |||||||||||||||||

| compression set | 20 | % | ASTM D395 | |||||||||||||||||

| Resistance after aging | 0.01 | Ω *cm | ENG-WI-550RevA2 | |||||||||||||||||

| density | 1.9 | g/cm3 | ASTM D792 | |||||||||||||||||

| Shielding energy efficiency | - | dB | MIL-DTL-83528E | |||||||||||||||||

| Operating temperature | -55-160 | ℃ | / | |||||||||||||||||

| Mold proof grade | 0 | / | GB/T 2423.16-2008 | |||||||||||||||||

Case Sharing

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

Case background 2: The customer's controller needs to be sealed with waterproof tape. It is required to reach the waterproof rating of IP67 and IP68 to ensure that the sealing is waterproof.

The use of our single-sided adhesive extrusion hollow rubber strip, through customer testing and verification, can well meet the customer's sealing and waterproof requirements.