The introduction of sealing silicone shielding strips, accompanied by the integration of conductive extrusion shielding strips, represents a significant advancement in the realm of waterproof sealing solutions. The combination of silicone as the primary sealing material and conductive materials such as nickel carbon, silver aluminum, and conductive cloth within the extrusion shielding strips ensures unparalleled protection against water ingress and electromagnetic disturbances. This innovative solution not only enhances the durability and reliability of various products but also showcases the industry's commitment to pushing boundaries and delivering state-of-the-art solutions.

| Availability: | |

|---|---|

| Quantity: | |

GC-SP -YT55

Gold-cool

ISO9001, ISO14001, UL, Rohs, IATF16949, Reach

Introducing our latest product, the Conductive Sealing Silicone Strip. Designed with precision and integrated with a conductive extruded shielding strip, this product showcases our commitment to providing cutting-edge solutions that go beyond industry standards.

These strips have been meticulously crafted to seamlessly blend with silicone material, forming a robust and waterproof barrier that prevents any moisture from seeping in. Additionally, the conductive extruded shielding strip acts as a protective layer, effectively blocking unnecessary electromagnetic waves that may interfere with the functionality of electronic devices.

With our Conductive Sealing Silicone Strip, you can trust that your equipment will be safeguarded against potential water damage and electromagnetic interference. Experience the excellence of our advanced solution and elevate your sealing needs to new heights.

Product Parameters

| Model | GC-SP -YT55 | unit | Testing Standard | |||||||||||||||||

| Sealing material | Silver Copper | / | / | |||||||||||||||||

| color | yellowish-brown | / | / | |||||||||||||||||

| Volume resistivity | 0.004 | Ω *cm | MIL-DTL-83528E | |||||||||||||||||

| hardness | 55 | Shore A | ASTM D2240 | |||||||||||||||||

| tensile strength | ≥2.0 | MPa | ASTM D412 | |||||||||||||||||

| elongation at break | 200 | % | ASTM D412 | |||||||||||||||||

| compression set | 20 | % | ASTM D395 | |||||||||||||||||

| Resistance after aging | 0.01 | Ω *cm | ENG-WI-550RevA2 | |||||||||||||||||

| density | 3.5 | g/cm3 | ASTM D792 | |||||||||||||||||

| Shielding energy efficiency | - | dB | MIL-DTL-83528E | |||||||||||||||||

| Operating temperature | -65-125 | ℃ | / | |||||||||||||||||

| Mold proof grade | 0 | / | GB/T 2423.16-2008 | |||||||||||||||||

Case Sharing

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

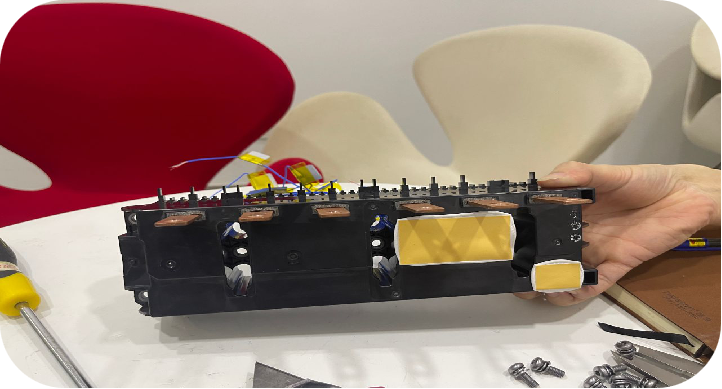

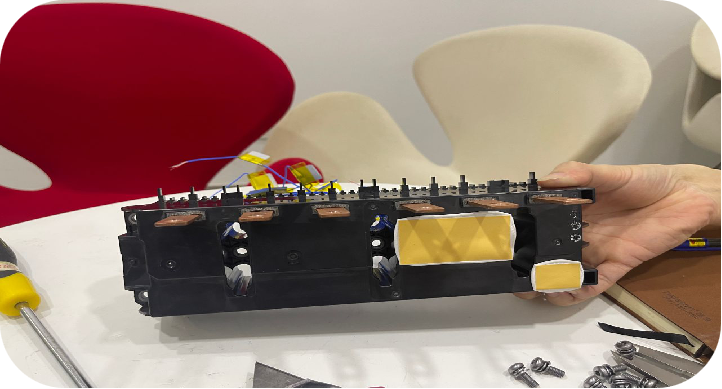

Case background 2: The customer's controller needs to be sealed with waterproof tape. It is required to reach the waterproof rating of IP67 and IP68 to ensure that the sealing is waterproof.

The use of our single-sided adhesive extrusion hollow rubber strip, through customer testing and verification, can well meet the customer's sealing and waterproof requirements.

Introducing our latest product, the Conductive Sealing Silicone Strip. Designed with precision and integrated with a conductive extruded shielding strip, this product showcases our commitment to providing cutting-edge solutions that go beyond industry standards.

These strips have been meticulously crafted to seamlessly blend with silicone material, forming a robust and waterproof barrier that prevents any moisture from seeping in. Additionally, the conductive extruded shielding strip acts as a protective layer, effectively blocking unnecessary electromagnetic waves that may interfere with the functionality of electronic devices.

With our Conductive Sealing Silicone Strip, you can trust that your equipment will be safeguarded against potential water damage and electromagnetic interference. Experience the excellence of our advanced solution and elevate your sealing needs to new heights.

Product Parameters

| Model | GC-SP -YT55 | unit | Testing Standard | |||||||||||||||||

| Sealing material | Silver Copper | / | / | |||||||||||||||||

| color | yellowish-brown | / | / | |||||||||||||||||

| Volume resistivity | 0.004 | Ω *cm | MIL-DTL-83528E | |||||||||||||||||

| hardness | 55 | Shore A | ASTM D2240 | |||||||||||||||||

| tensile strength | ≥2.0 | MPa | ASTM D412 | |||||||||||||||||

| elongation at break | 200 | % | ASTM D412 | |||||||||||||||||

| compression set | 20 | % | ASTM D395 | |||||||||||||||||

| Resistance after aging | 0.01 | Ω *cm | ENG-WI-550RevA2 | |||||||||||||||||

| density | 3.5 | g/cm3 | ASTM D792 | |||||||||||||||||

| Shielding energy efficiency | - | dB | MIL-DTL-83528E | |||||||||||||||||

| Operating temperature | -65-125 | ℃ | / | |||||||||||||||||

| Mold proof grade | 0 | / | GB/T 2423.16-2008 | |||||||||||||||||

Case Sharing

Case background 1: Customer drawer structure, conventional thermal conductivity materials because of silicone has skid resistance, easy to damage in the drawing process, assembly trouble.

The use of high cool p series (with PI), E series (with silicon tape) in the premise of meeting the temperature rise requirements, can solve the customer assembly difficulties; After testing and verification, the final customer chose our company's GC-TP-200P6-1, which effectively solved the customer's assembly difficulties.

Case background 2: The customer's controller needs to be sealed with waterproof tape. It is required to reach the waterproof rating of IP67 and IP68 to ensure that the sealing is waterproof.

The use of our single-sided adhesive extrusion hollow rubber strip, through customer testing and verification, can well meet the customer's sealing and waterproof requirements.